How to Digitize and Optimize Product Data

Many companies are facing the same problems when it comes to product data, but don’t know which IT solutions can help them. In this article, we present a strategy to optimize your product data management and create a competitive advantage.

1. Initial situation and challenges

Senders of product data can be manufacturers, suppliers or wholesalers. Employees of these companies may spend a lot of time editing product data for different markets, customers and sales channels. Existing ERP systems are insufficient to cover all relevant data for all customers and markets. The product card can easily become too big and complex for anyone to work with. Customers may often have special requirements concerning product data, and will query unclear statements. Moreover, to reduce time and manual work on their side they would like to receive data in a structured form directly into their IT System.

Receivers of product data can be retailers, wholesalers, end customers or market places. These companies receive product cards in various ways (PDFs, lists, Excel files, EDI data). Therefore, employees may spend a lot of time entering data in the respective IT system. The information sent may often be unclear and incomplete, which requires further communication. Certain departments such as logistics and marketing need more than just the standard product data and have several rules in place, which suppliers don’t follow. Also on their side, existing ERP systems are insufficient to cover all relevant data for all markets. The product card easily becomes too big and complex for anyone to work with.

2. Solution

Generally, the producers and suppliers are best informed about product data and should provide this information to their customers in a form that is complete, correct, structured and up to date. This is a matter of competition, since suppliers who provide great product data quality are obviously favored by clients.

A tool is needed to create an effective communication channel between senders and receivers of data. Senders need to know exactly which data are required legally per country, as well as any customer-specific wishes. Such an overview can easily be provided in a web form, or as automatic validations when EDI data are exchanged.

3. The efficient digital exchange of product data

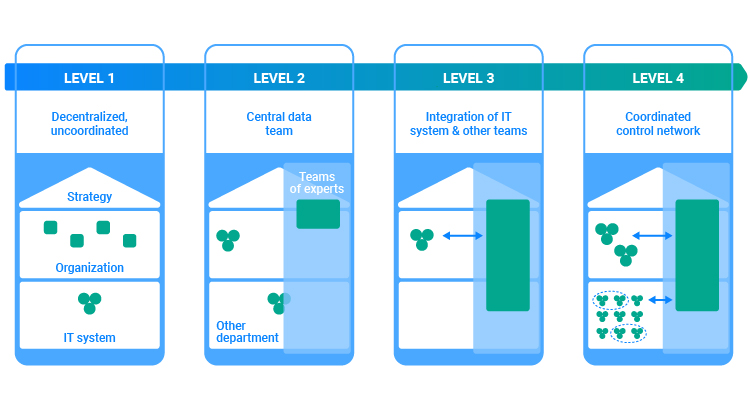

An MDM system acts as a central data collector unifying various data silos of your own company environment as well as your business partners’ systems. But how does it work? We will look at several use cases: manual and semi-manual entries, and EDI supported data flows.

3.1 Core process

The foundation of all processes is the MDM data pool with its web-interface. A data sender can log into the website and create a new product. Therefore, they need to choose certain factors which will determine what information they have to enter and which rules apply for the entered values.

| Product creation feature | Resulting rules and validations |

| Product category |

|

| Target market |

|

| Data receiver |

|

After entering these values, the MDM opens a very clean product card where all relevant information for the entered product card factors is displayed. Mandatory fields are marked as such. Each field has a help text describing exactly what information is to be entered and which rules apply (for example, character limits). These rules are very important as they make it impossible for the sender to enter incorrect data. For example, all weights of products and packages, as well as prices with taxes, transport fees and so on, are either automatically calculated or checked by the system. To reduce time, the same product card may be copied and published for a different market. Only extra information that is required for this market but not present on the original card must be entered in that case. The same goes for product updates.

The receiver can implement a simple or complex workflow which may include various departments to check who has the option to change or add values such as marketing descriptions or SEO keywords on product cards received. Of course, it is possible to make correction requests or ask questions with a chat function. If desired, even price negotiations can be conducted with MDM. Such information may also come as enrichments from integrated EDI, ERP or other IT systems.

Finally, the product information arrives in the receiver’s desired IT system, which besides ERPs and material management systems may include online shops, PIMs and whichever other tool you may use. As the data are structured, any manual effort is eradicated. Due to the previous checks, only complete, correct and current data enter your internal systems.

The sender and receiver may access the MDM at all times to browse through all present and past product cards, logs and previous communications. You can even use this record of product data to conduct tenders and procure new items.

3.2 Special use cases

While SMEs may compete for your satisfaction and are happy to receive access to MDM, very large or single-sourced suppliers may consider it a burden. You can receive their product data through integration with their existing data pools (e.g. GDSN). Alternatively, integration can be established with the sender’s IT system. Only when data are missing or incorrect do they have to log in to MDM or, if desired, send the corrected product card.

On the other hand, very small suppliers may struggle with your requirements. They need the MDM to be very easy to use and self-explanatory. Of course, we can offer training for them, too. If you require any product images, you can offer them a search in the database of a third-party image provider.

As a sender using MDM, you may also provide your product data to other data pools (such as GDSN) used by your clients.

For each use case, a fitting solution exists.

4. What you need to do

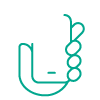

We have presented only a fraction of the technical possibilities here, and there is much more to talk about. But before going into further detail, we recommend the establishment of a dedicated internal expert team and process owner. Bearing in mind the first image in this document, there it is often the case that there is no central product or master data team, and information is spread across various departments. Therefore, a project starts by assigning roles and responsibilities. Once clarified, the team must explore and understand stakeholders, departments and IT systems which form the current processes. Only then can requirements analysis for an MDM Tool can start.

A qualified provider will help you understand the possibilities for the digitization of your company-specific use cases and processes. So, during provider analysis, it is recommended to use their consulting and project experience to address your challenges. As the introduction of an MDM tool often means the creation of entirely new processes, you may want to consider a proof of concept or a phased deployment of MDM functions. This allows you to re-evaluate your decisions and use the MDM system optimally.

If you require support in the early stages of considering an MDM system, please feel free to contact us.

If you want to know how MDM can help you create a competitive advantage, please find our white paper on this topic here