Comarch IoT MES

Comarch IoT MES

Advanced Manufacturing Management SystemCutting-edge software

to increase production efficiency and OEE

This a touchscreen supporting operators’ work. It displays necessary information on executed production orders and operators, including the current OEE indicator. It allows downtime to be declared, and reports about the current production status or quality control. Data may be entered using the touchscreen, a connected keyboard, or a code scanner.

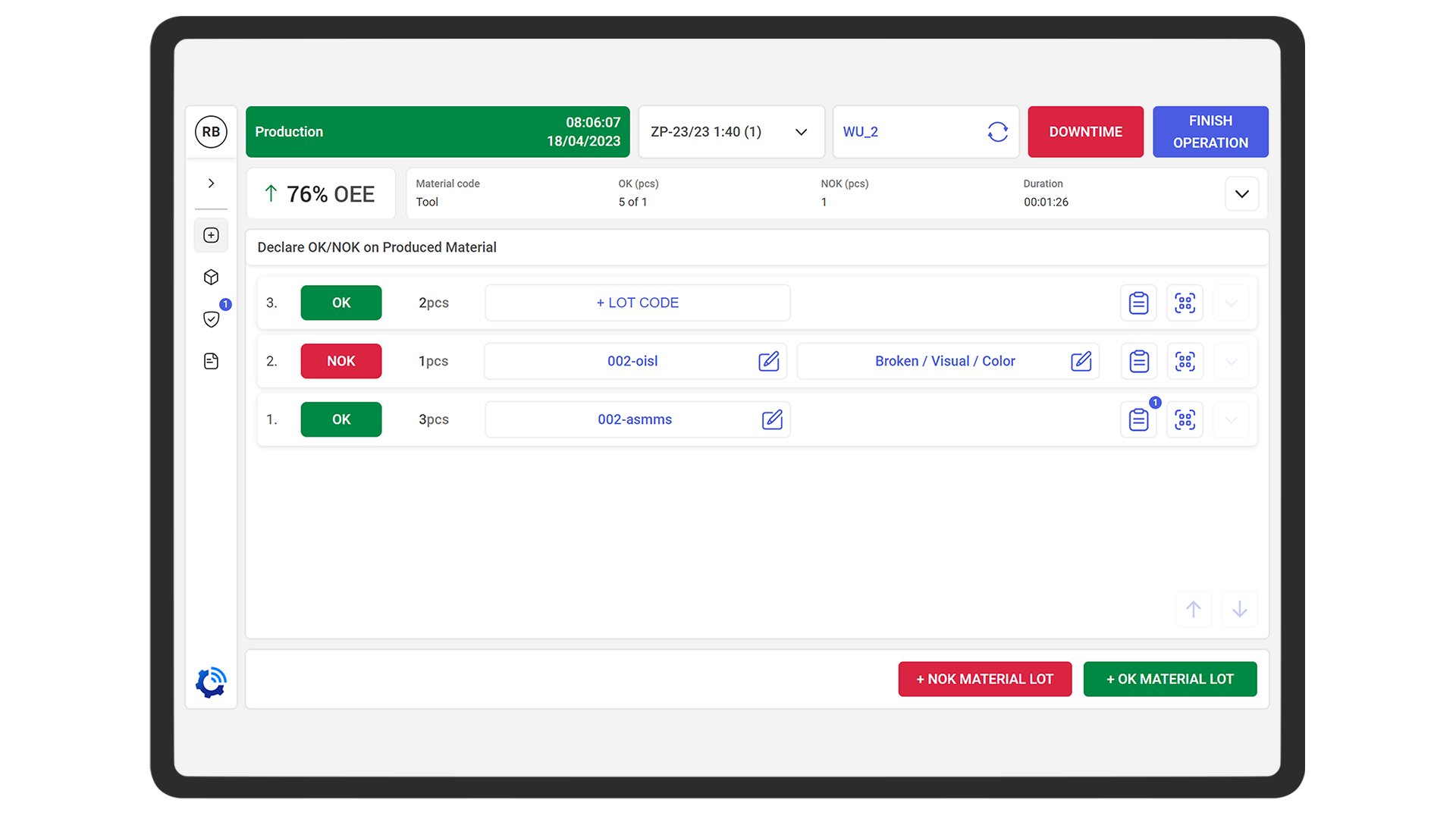

The OEE indicator is one of the most important coefficients for measuring production efficiency. OEE is calculated as the product of three manufacturing components: availability, quality, and performance. Analysis of the OEE indicator allows the detection of bottlenecks, which limit the overall efficiency of machines/production lines. Also, it shows where losses occur in the production process.

Calculate OEE, define other indicators, and track them all, improving the efficiency of your production processes.

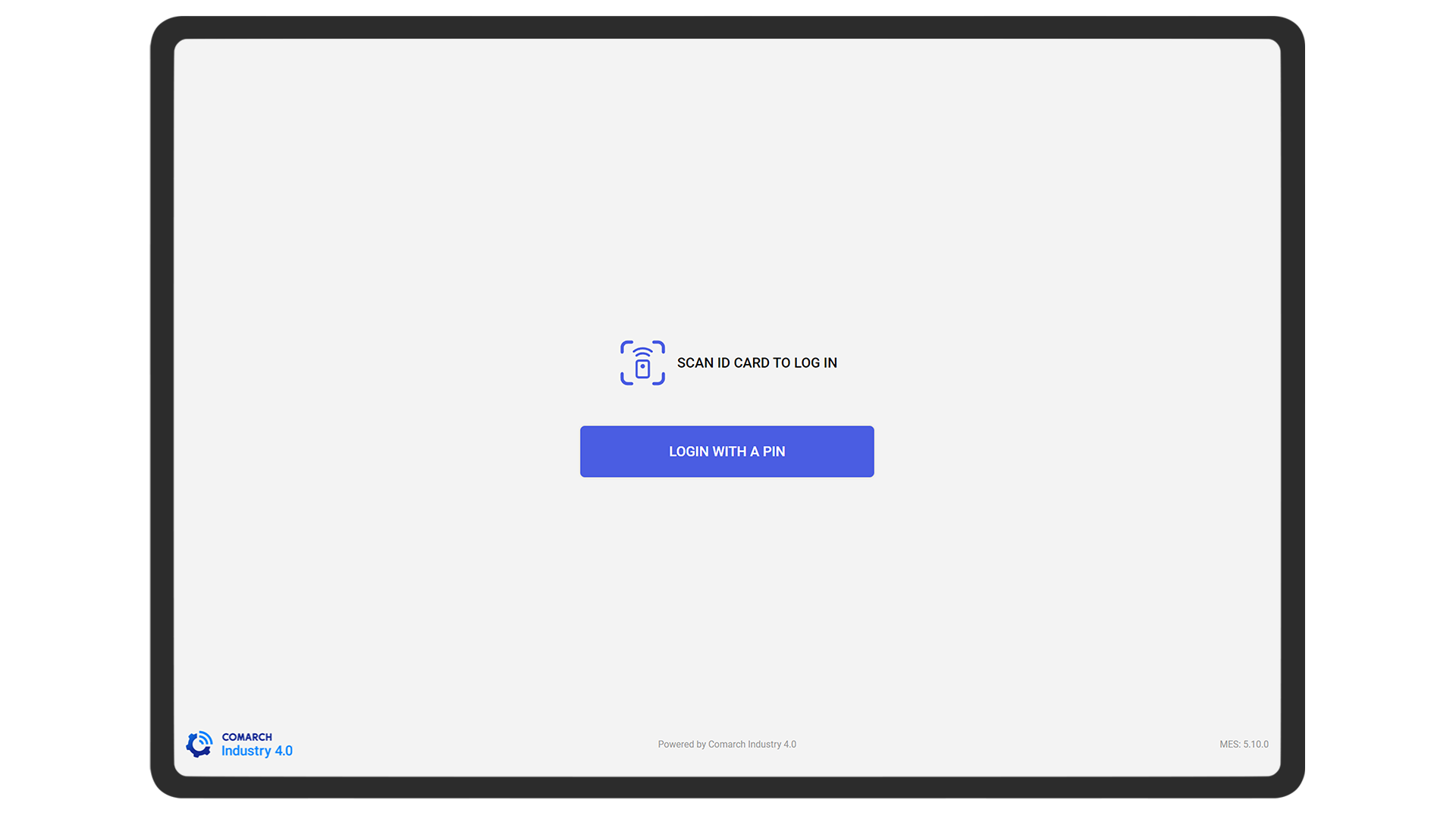

To sign in to the application, you can use a login and password or an access card. Access to individual machines is limited by an authorization system that automatically verifies and checks whether a machine’s operator has been provided with appropriate permissions and trained to work on a given workstation.

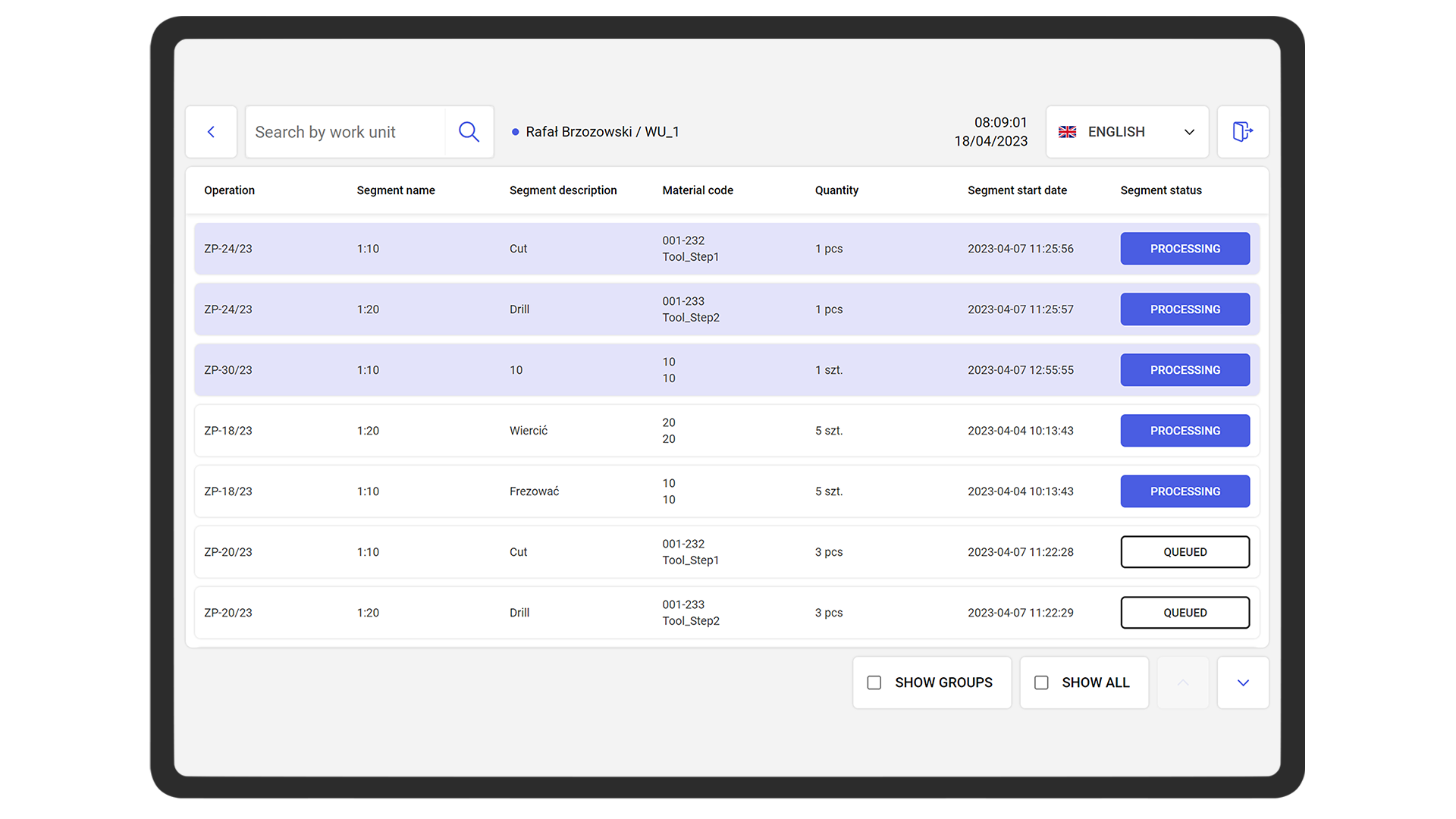

Thanks to digital data exchange, the operator can select a production order, prepared and planned especially for that operator, in the MES application panel. Before starting work, it is possible to check detailed information about a given order, such as the number of pieces to be made or the time of operation.

You can also decide whether to start a changeover or proceed directly to production. The operator independently selects the operation to be performed from among all operations assigned to the current workstation. The sequence of operations may be planned beforehand in external APS systems and presented as prompts to the user.

The system allows establishing a permanent connection with machines in order to read currently available signals (such as status and working time), emerging alerts, and information on the number of pieces produced. As a result, you receive reliable data on the status and execution of a production order in real time.

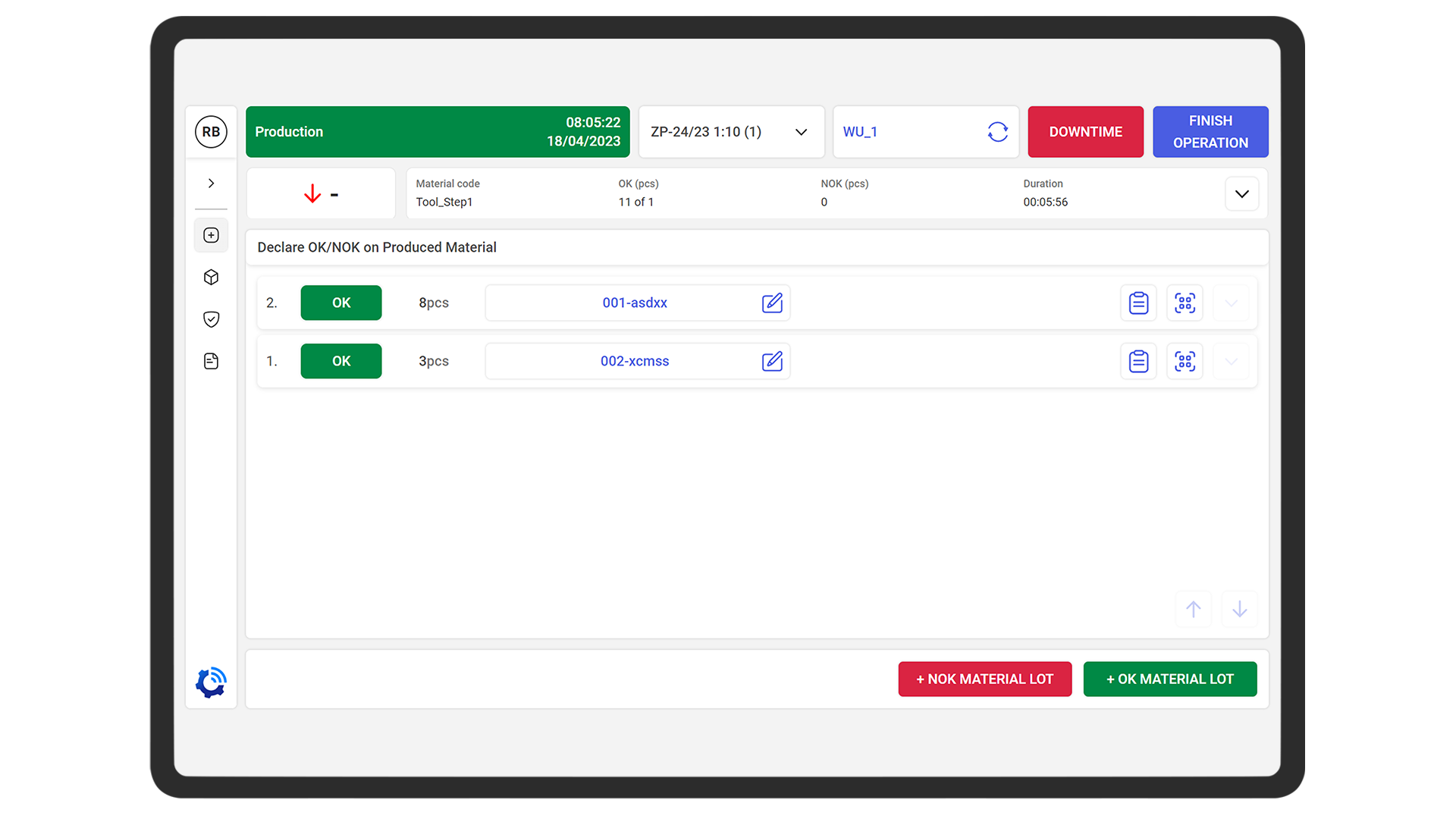

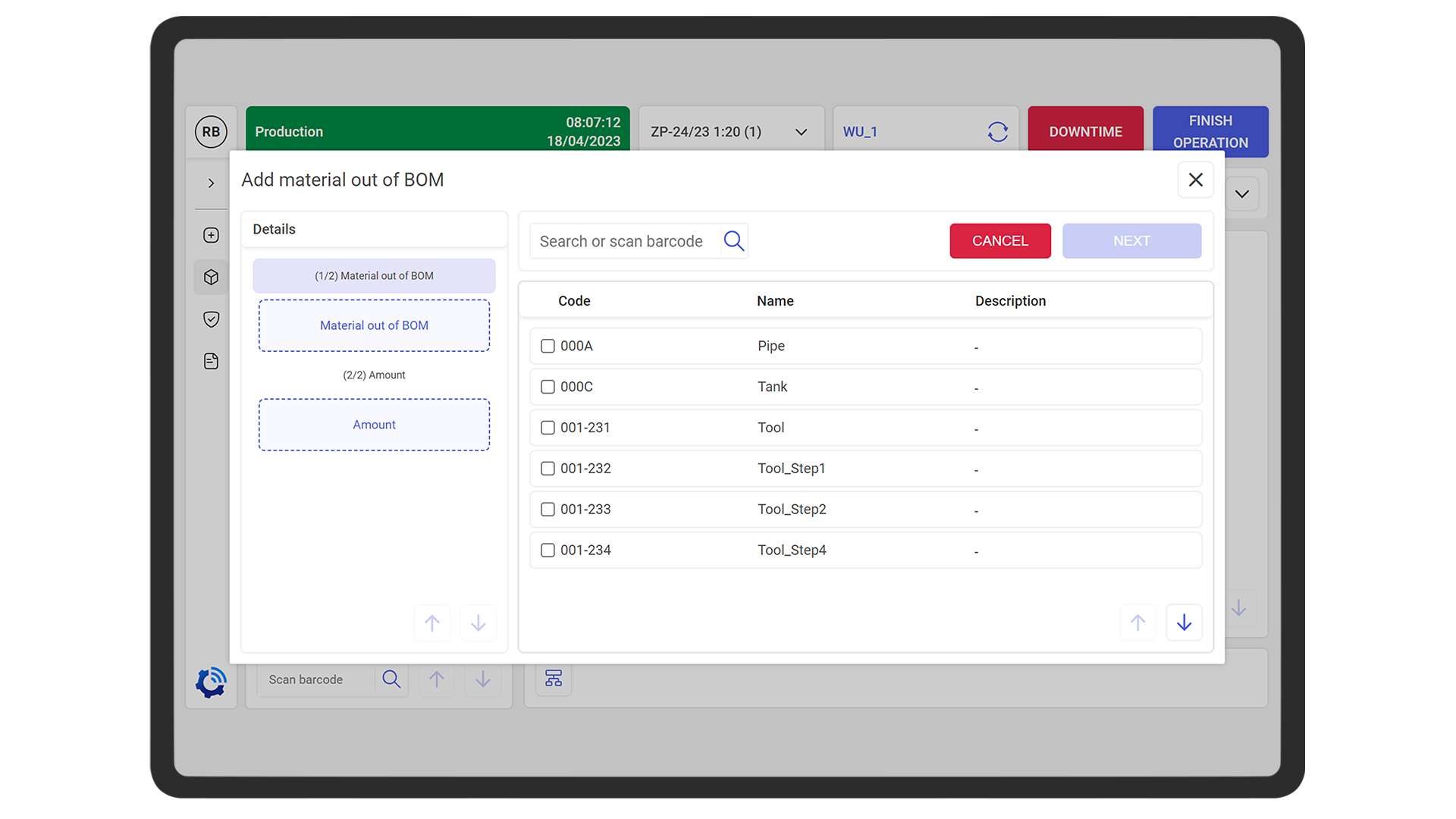

Integration with an ERP system allows the constant tracking and control of used materials. The quantity of manufactured goods is declared automatically (based on a signal from a machine) or manually, using the production panel.

The employee can view a bill of materials (BOM) assigned to a current operation and declare the utilization of individual materials and non-conforming goods. This makes it possible to monitor the quantity and quality of materials used.

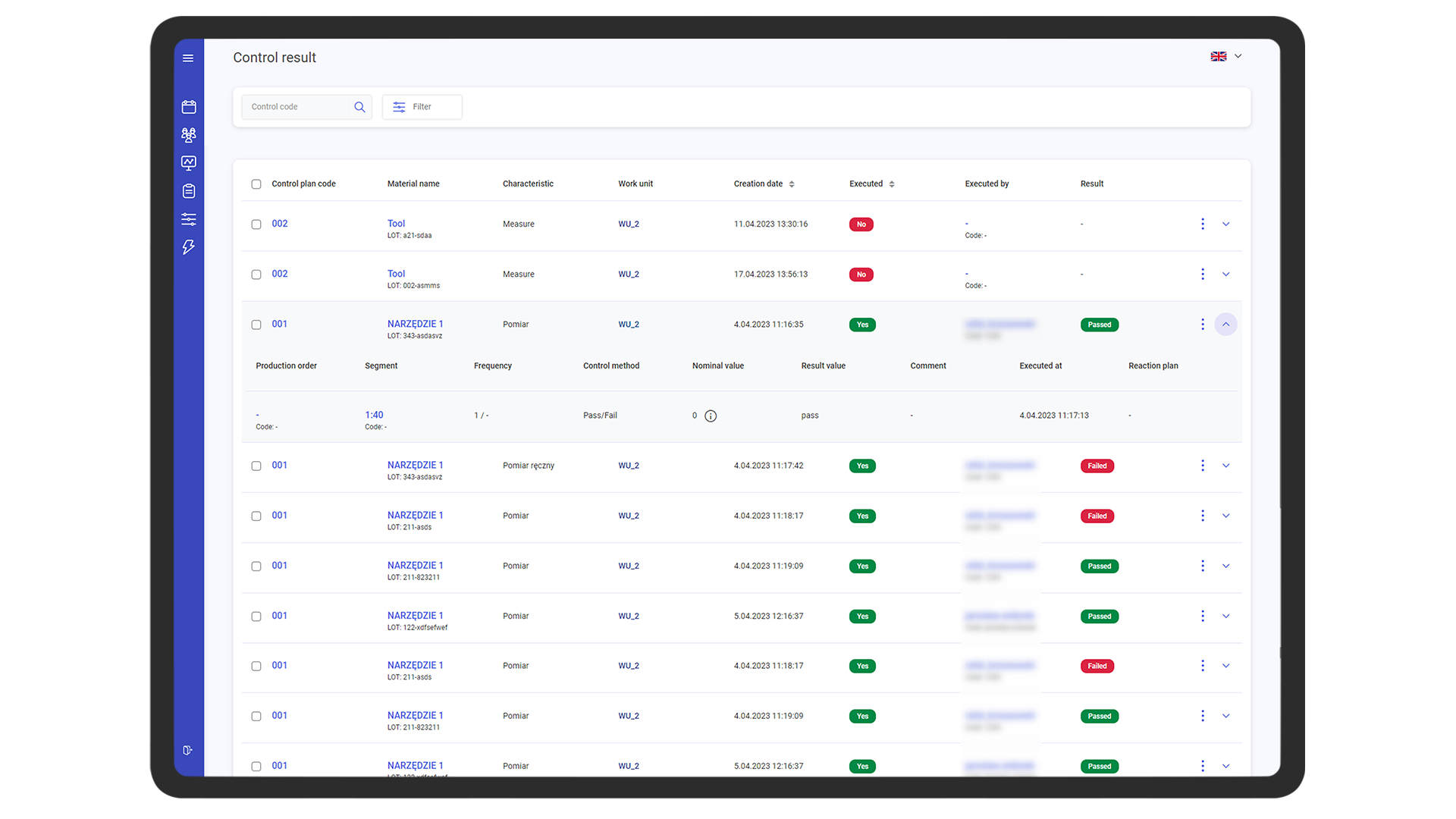

Quality control plans allow the ongoing monitoring of product quality, eliminating non-conforming products, which reduces production costs significantly. The integration of MES with QMS systems and the digitization of quality control plans make it possible to avoid creating piles of paper documentation, guiding the operator in a simple way through control and measurement activities.

Operators can press a button that automatically reads a measurement from a device that made it, with no need to perform the entire operation manually.

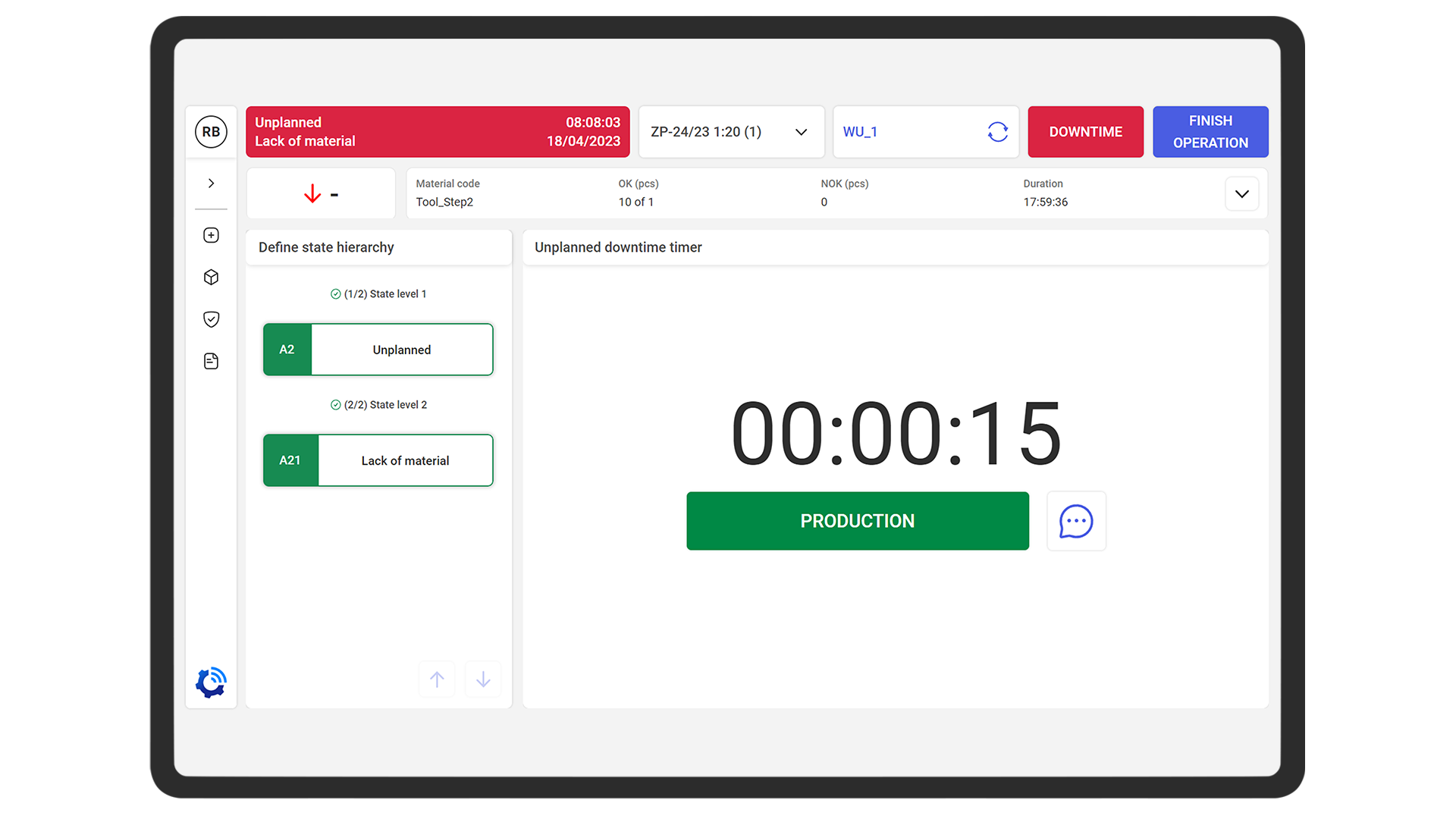

Machine downtime can be registered automatically (based on a signal from a machine) or manually through an operator’s interaction with the system.

The operator can define the reason for a period of downtime and indicate whether it has been planned. The end of such a period may also be reported automatically or manually, and the entire event history is stored in the database.

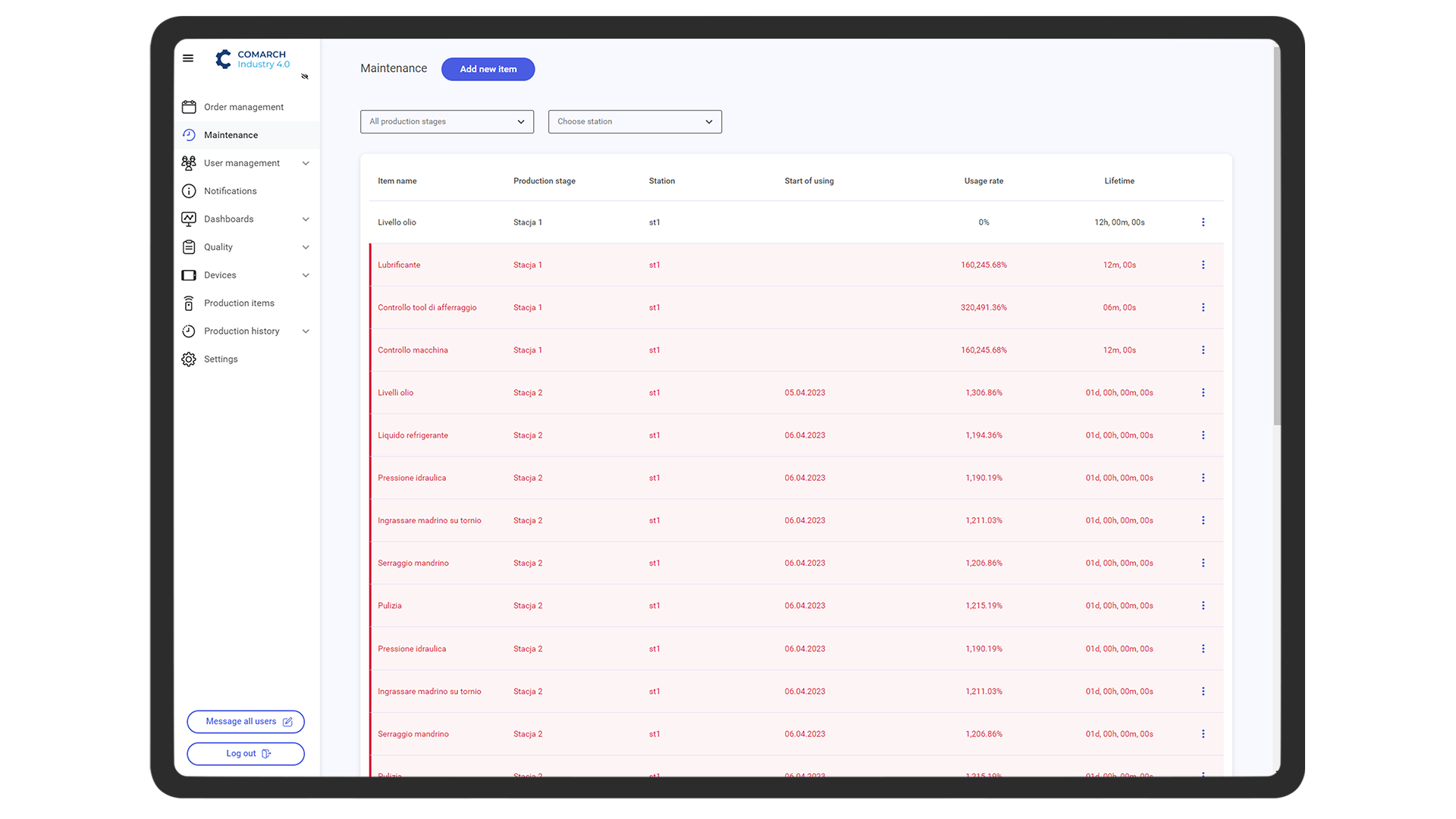

The maintenance module allows users to assign periodic service activities to each machine, specifying their time range and accordingly counting the employee-hours needed to perform them.

Information on the current status is available in the production panel and in the office part of the system. Employees are reminded of the need to perform service tasks by relevant notifications.

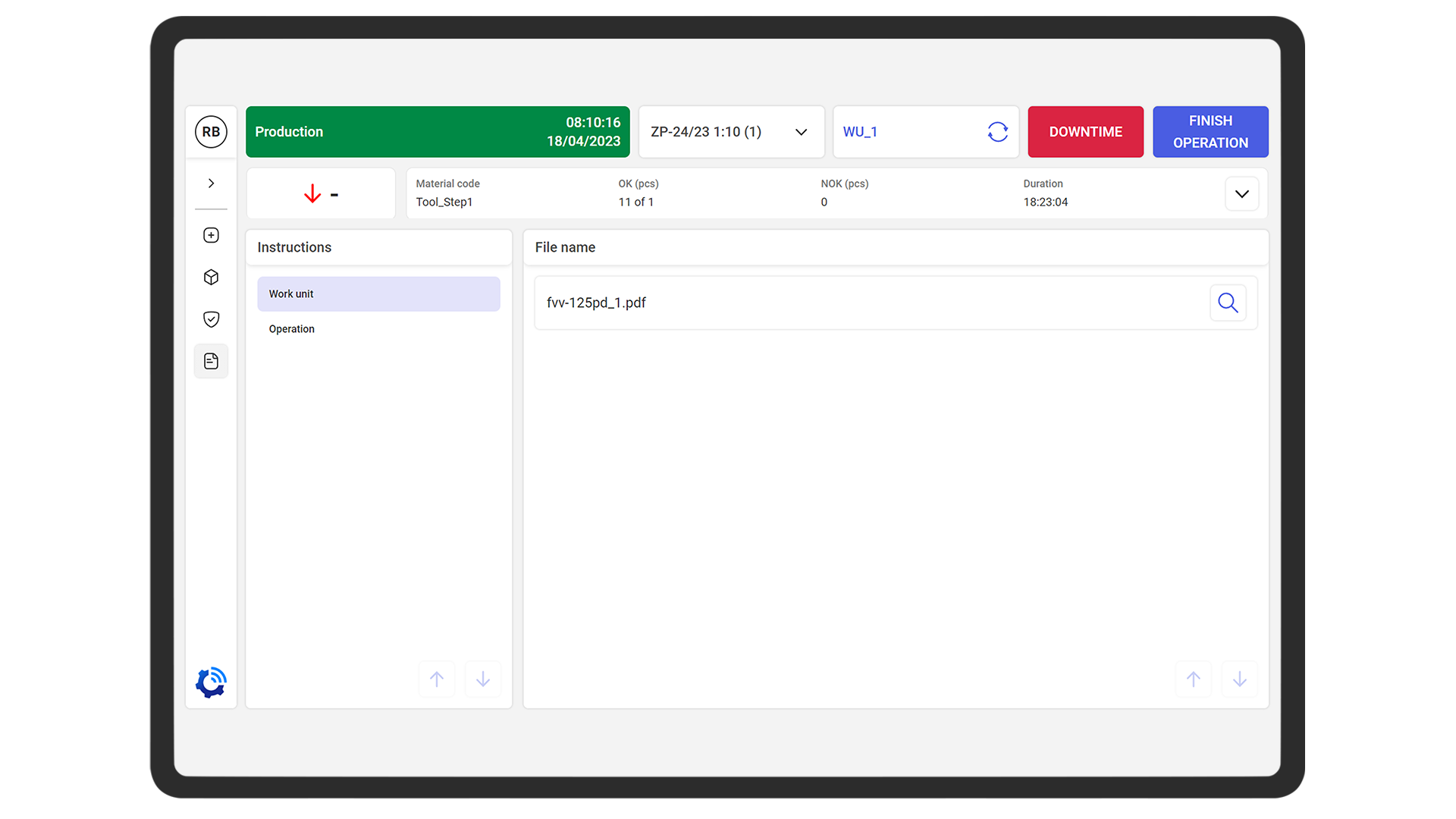

At any time, operators can view technical drawings, instruction files attached to a selected workstation or operation, technical documentation, and other attachments intended for employees in the application panel.